It's been a while since I last updated the Mazda Infotainment System. Last time it went very smoothly without issue, so I was keen to rinse and repeat the process as my local Mazda dealers don't seem that keen. The task itself is surprisingly simple, but it needs babysitting and if you're a bit of a luddite it might seem a bit daunting. Don't worry, it really is plug-n-play. And if you follow the supplied instructions carefully you won't have any issues.

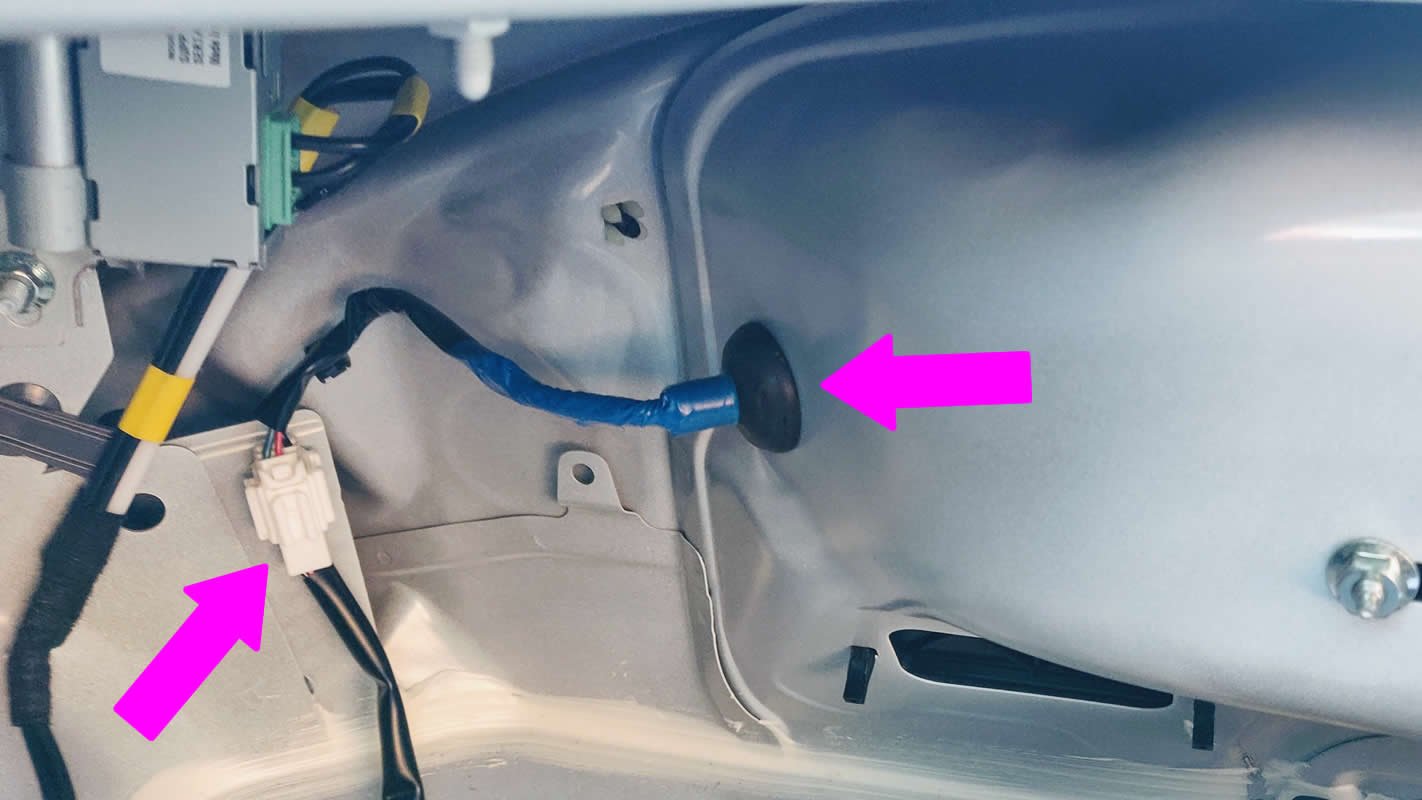

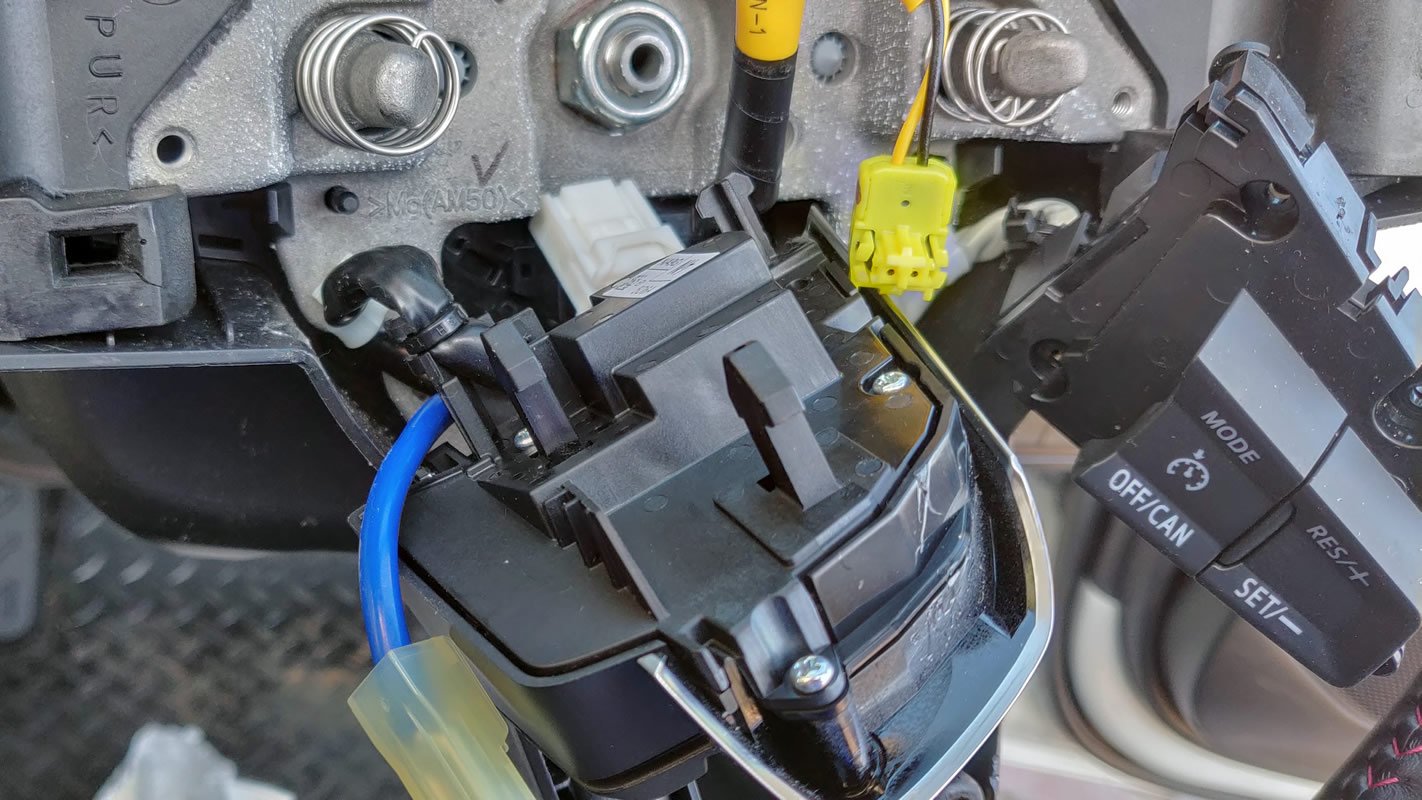

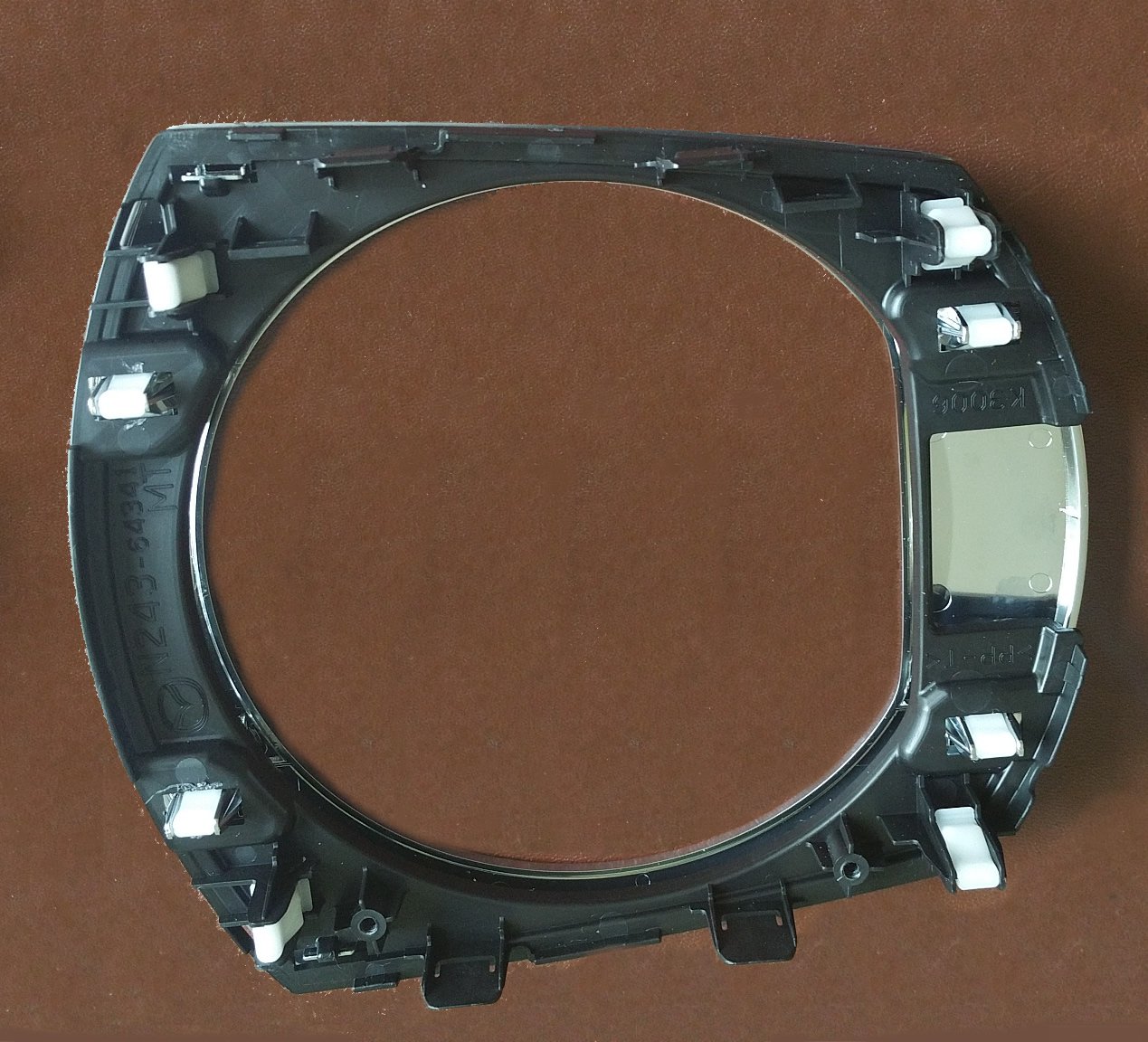

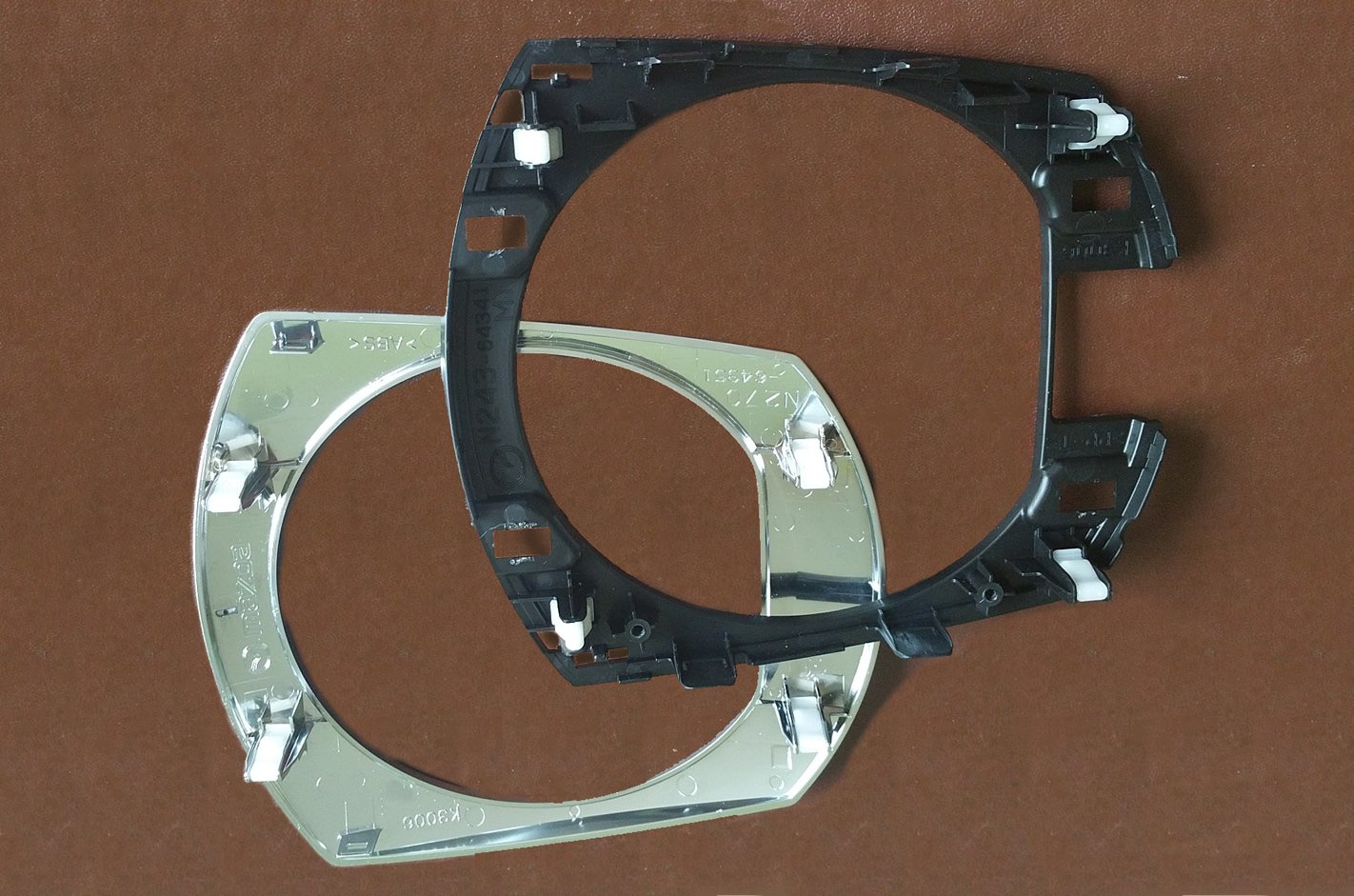

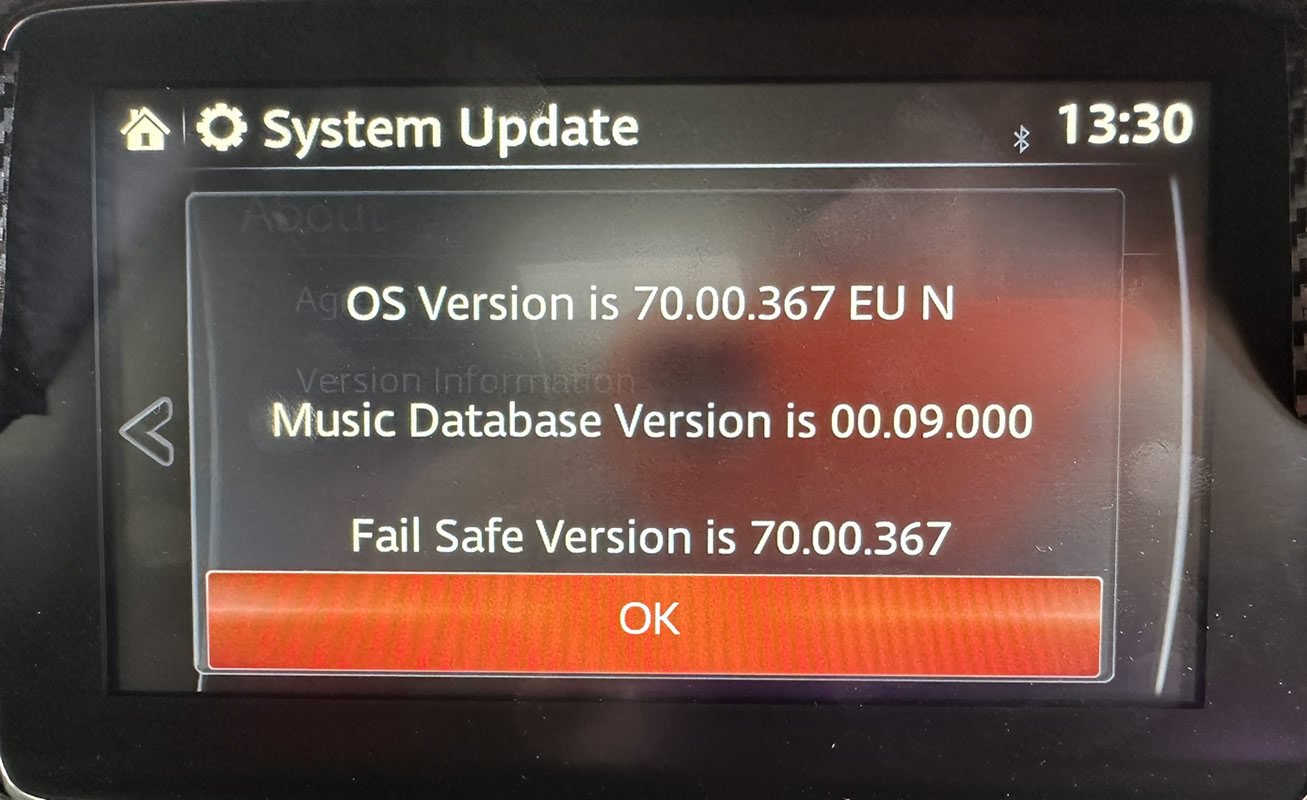

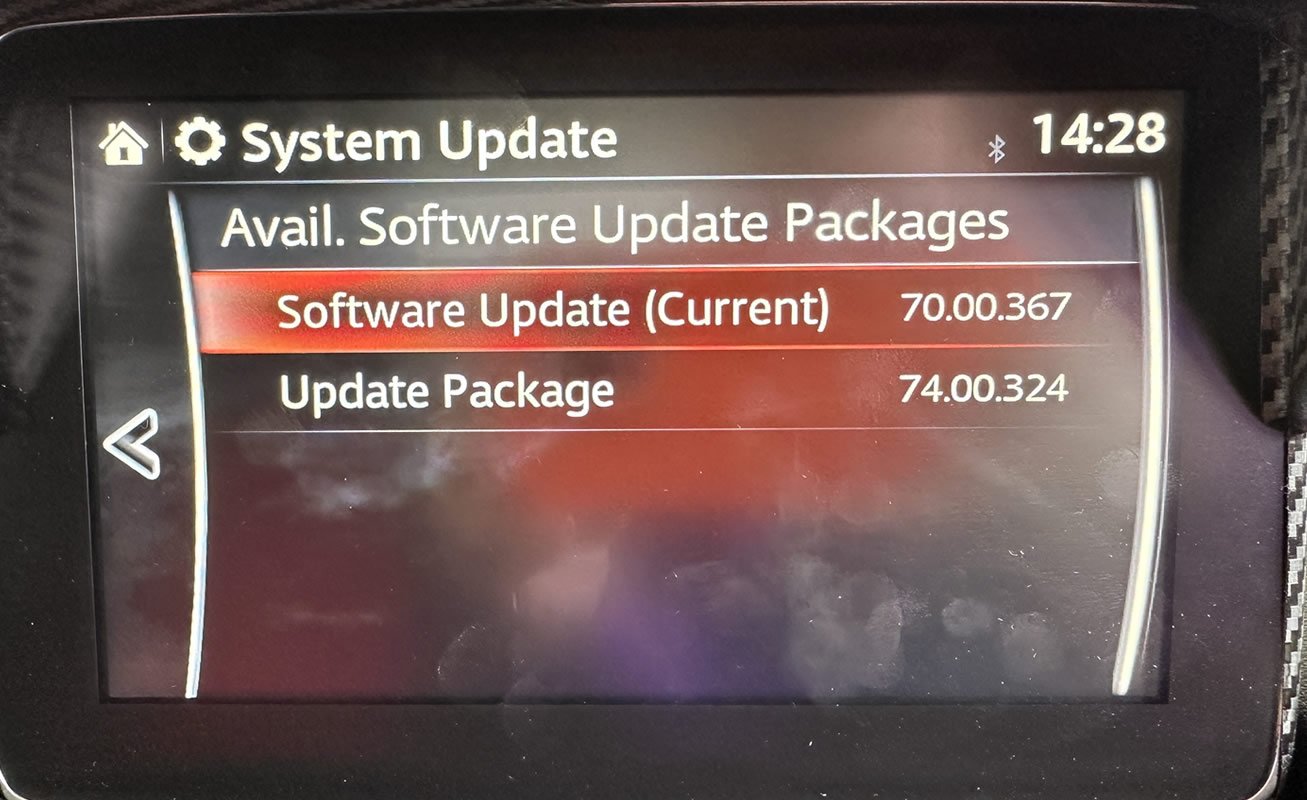

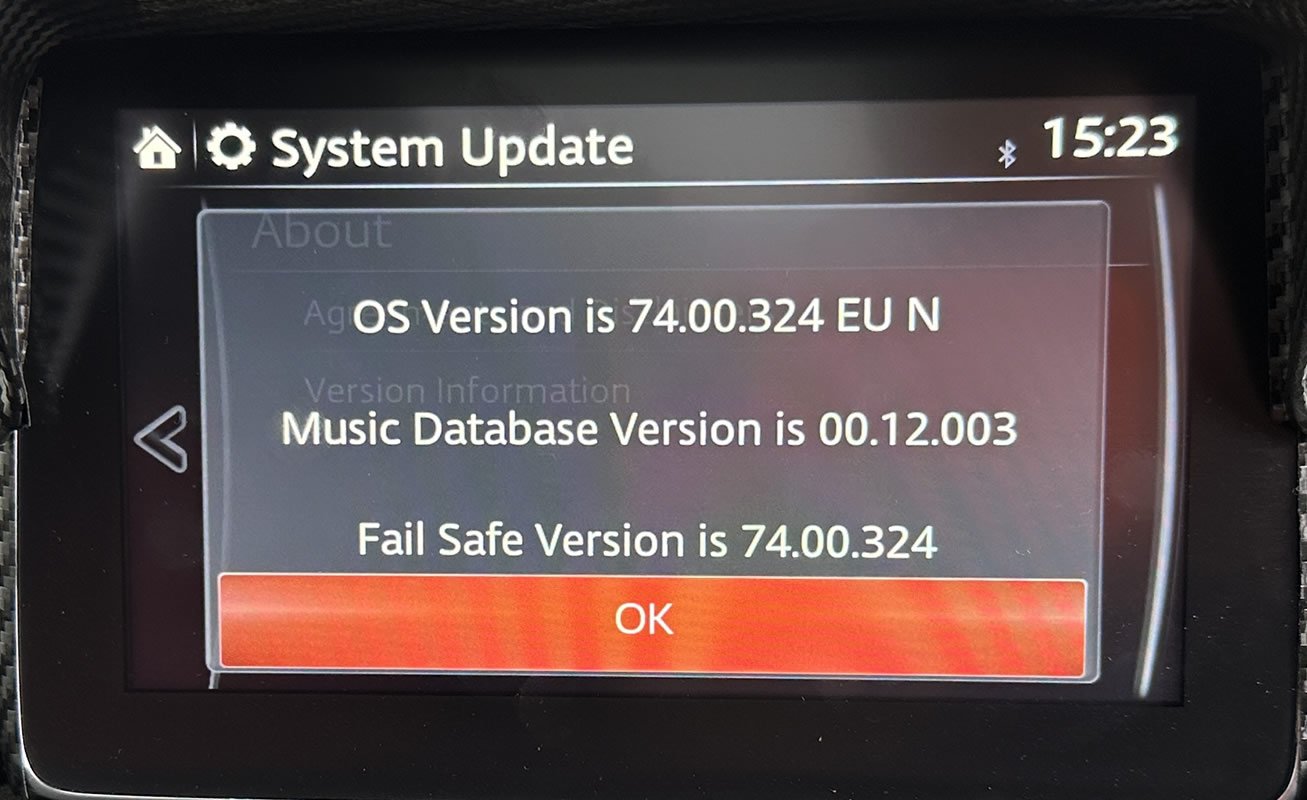

My Mx-5 had been upgraded with the required hardware needed for Android Auto / Apple Carplay hardware back in 2019, and I'd subsequently upgraded the firmware back in 2021 (see older post). Once again this upgrade was purely software-related. Before I began my software version was 70.00.367 EU N and the version I was about to install is 74.00.324 EU N - and as before I could upgrade to this version in a single step.

(If your MX-5 isn't on version 70, please make sure you read my previous post as you will not be able to perform the update I'm describing here until you've met initial requirements.)

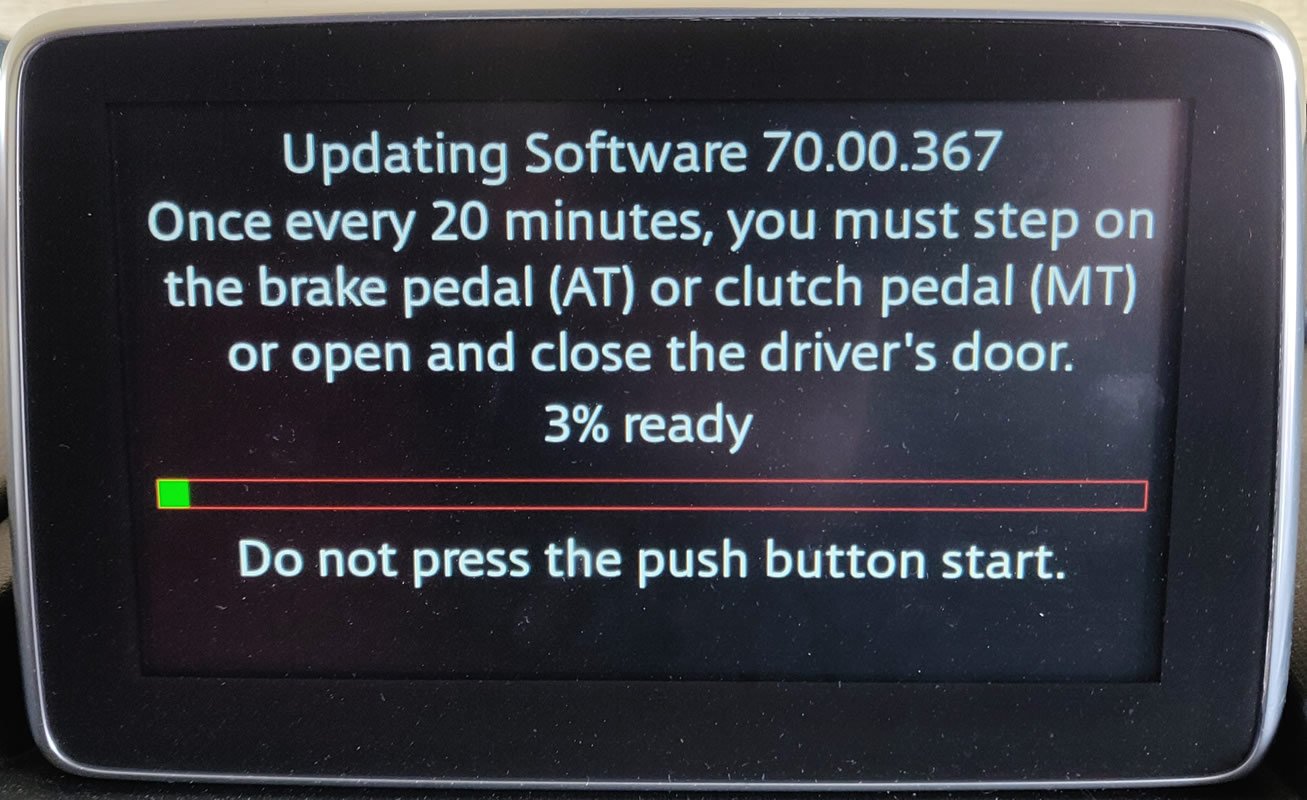

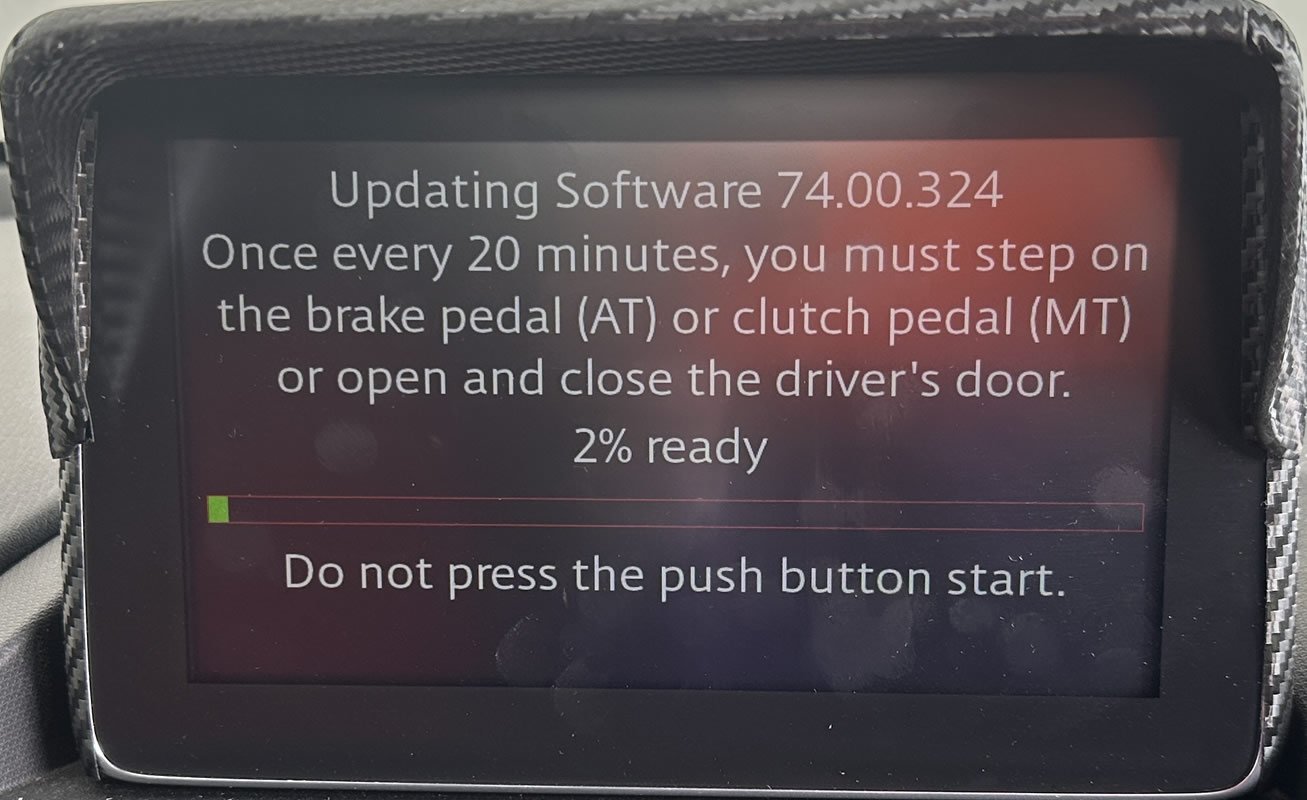

I remembered needing to depress the clutch pedal once the update is in progress, to prevent the idle time from wrecking the upgrade. After you've installed the memory stick with the upgrade and started the process you'll see a message showing your options.

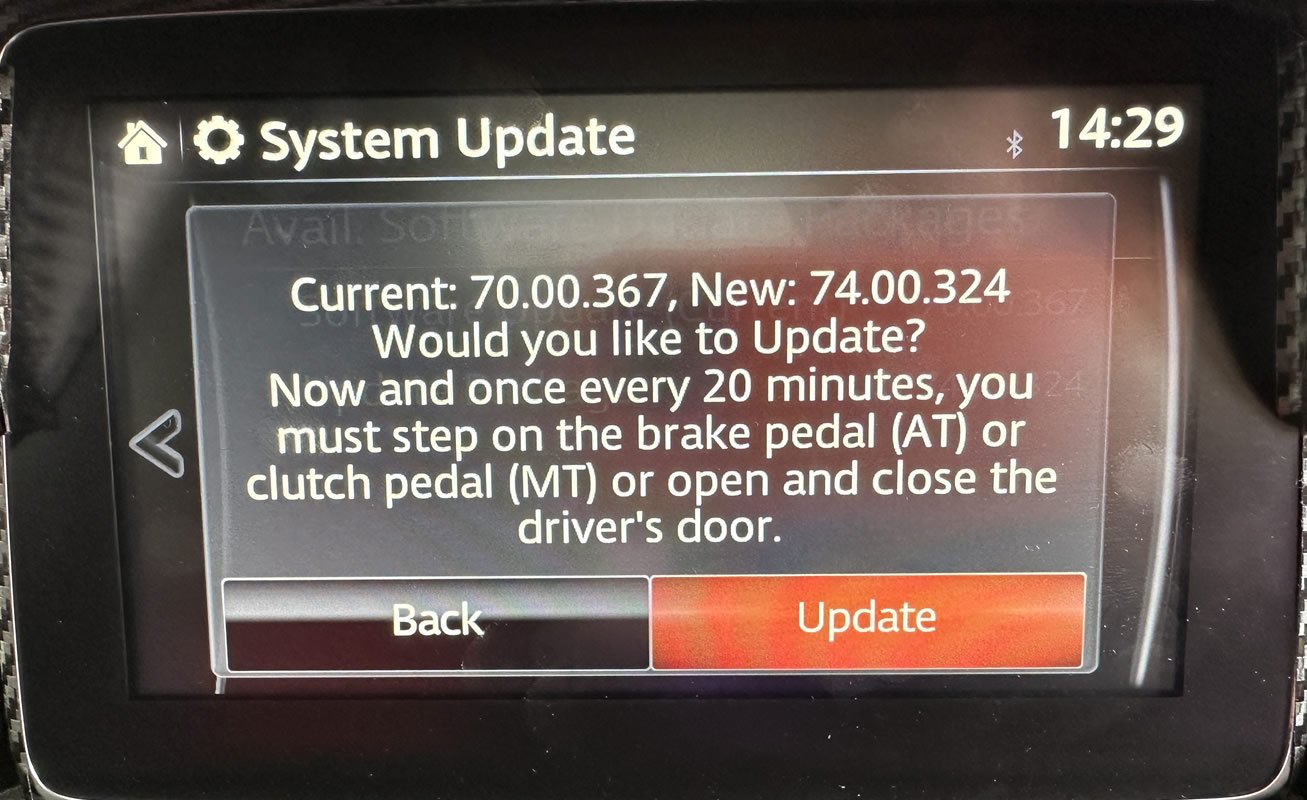

Select the update package and press down to confirm your selection. You'll then need to confirm the selection. I always appreciate these fail-safe procedures, as they can prevent nasty surprises if you've clicked something by accident. As this is intended, I selected update and pressed to confirm.

It's worth noting that this is the last opportunity you have to safely exit the process.

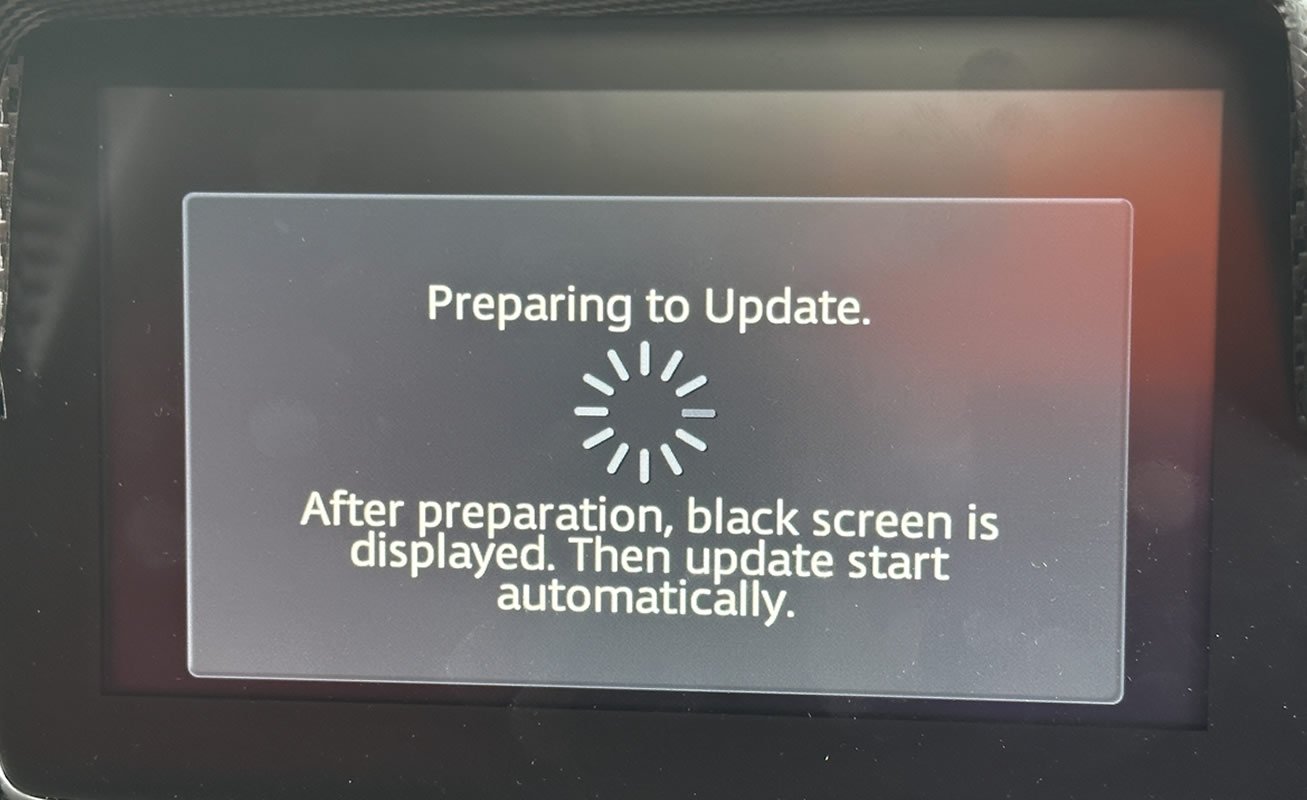

After this you'll see a loading screen. I'm mentioning this specifically because this is the one time you've got to belt yourself in and keep your hands off. It's going to take a while to cook and you mustn't give up, nor start catastrophising that it's been 'loading' for ages and therefore has to have borked the whole thing. Hang in there. It'll be fine, provided the update file was copied diligently to the USB. For those that need to know all the details, my educated guess as a software developer guy is it's copying the files off the USB. And this defo isn't a USB 3 setup, so it'll chug along like a tortoise and not race away like a hare.

Once the files are prepared you'll see a message on screen advising how far through the update is and crucially that you need to depress the brake or clutch pedal every 20 minutes. As before, I strongly urge you to set a timer and press the clutch pedal every 15 minutes to prevent the idle timer from turning off the media system.

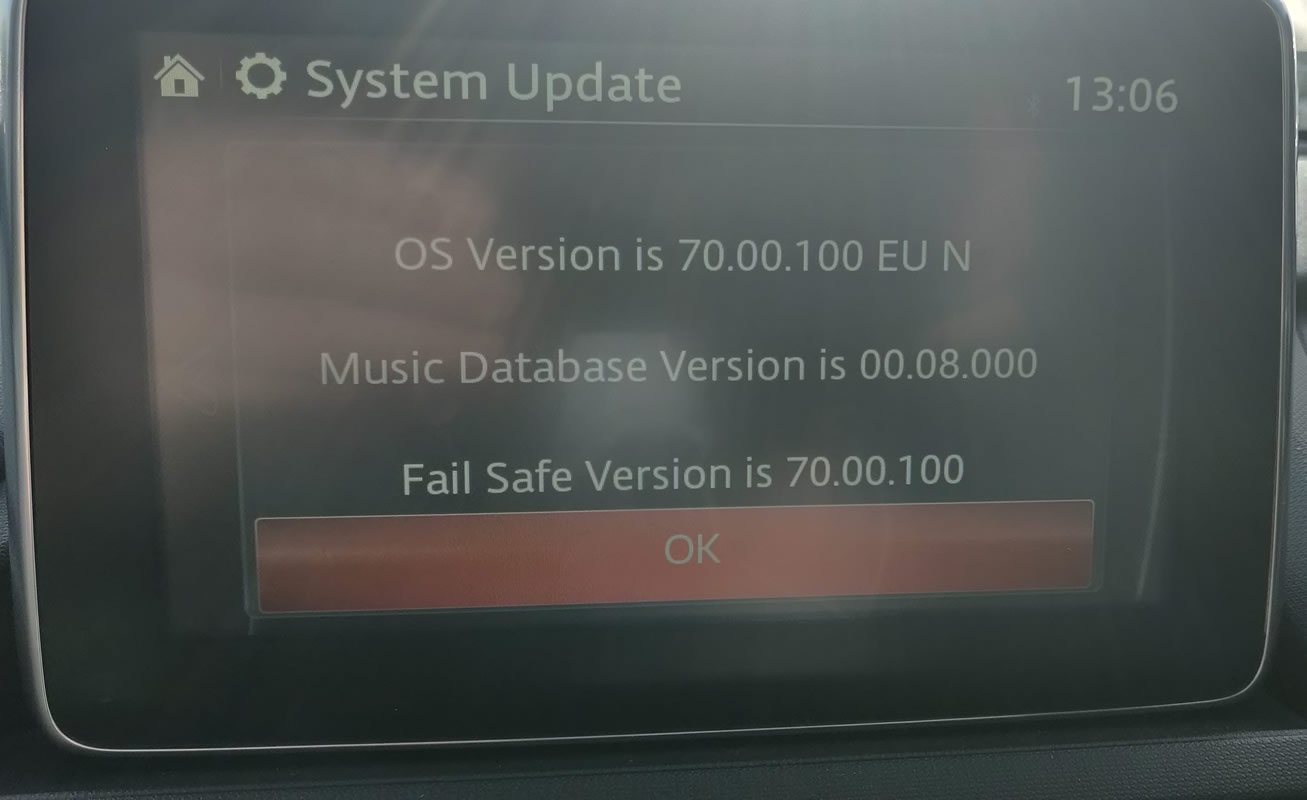

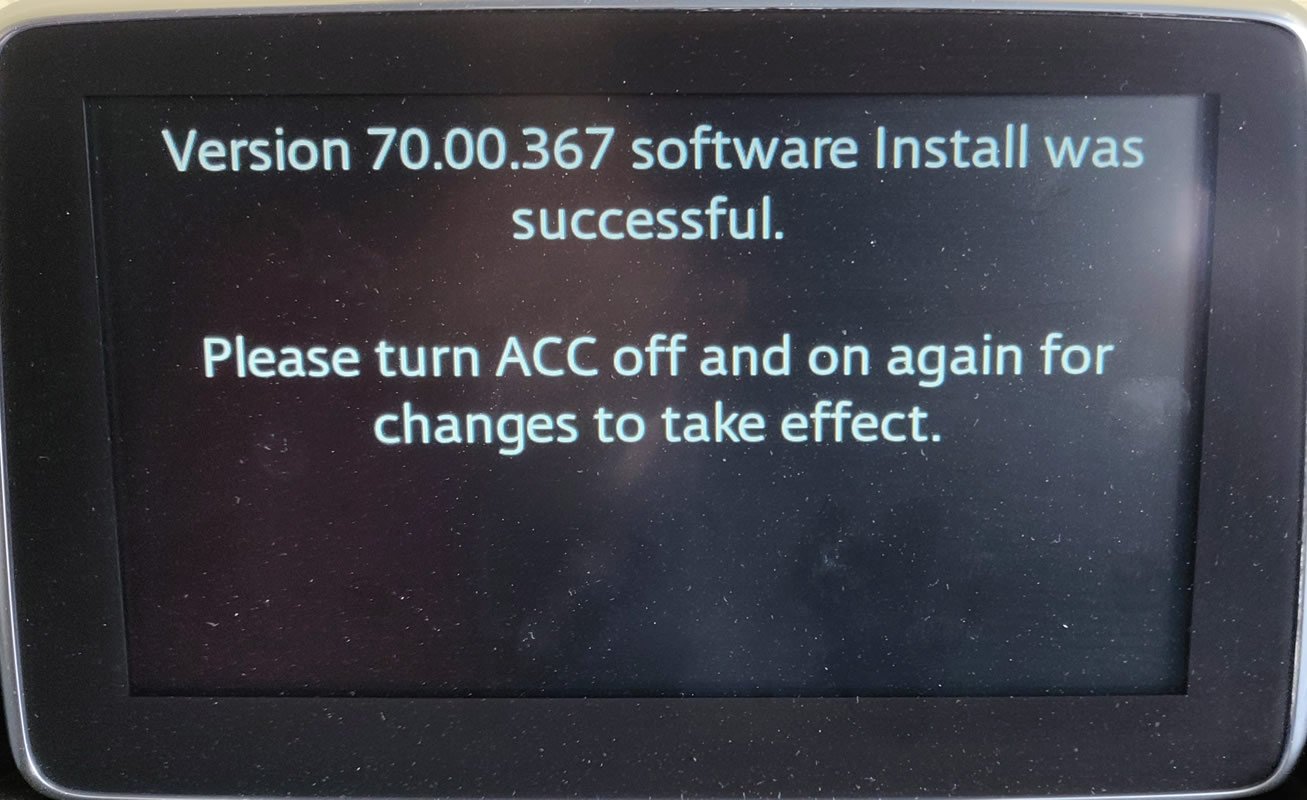

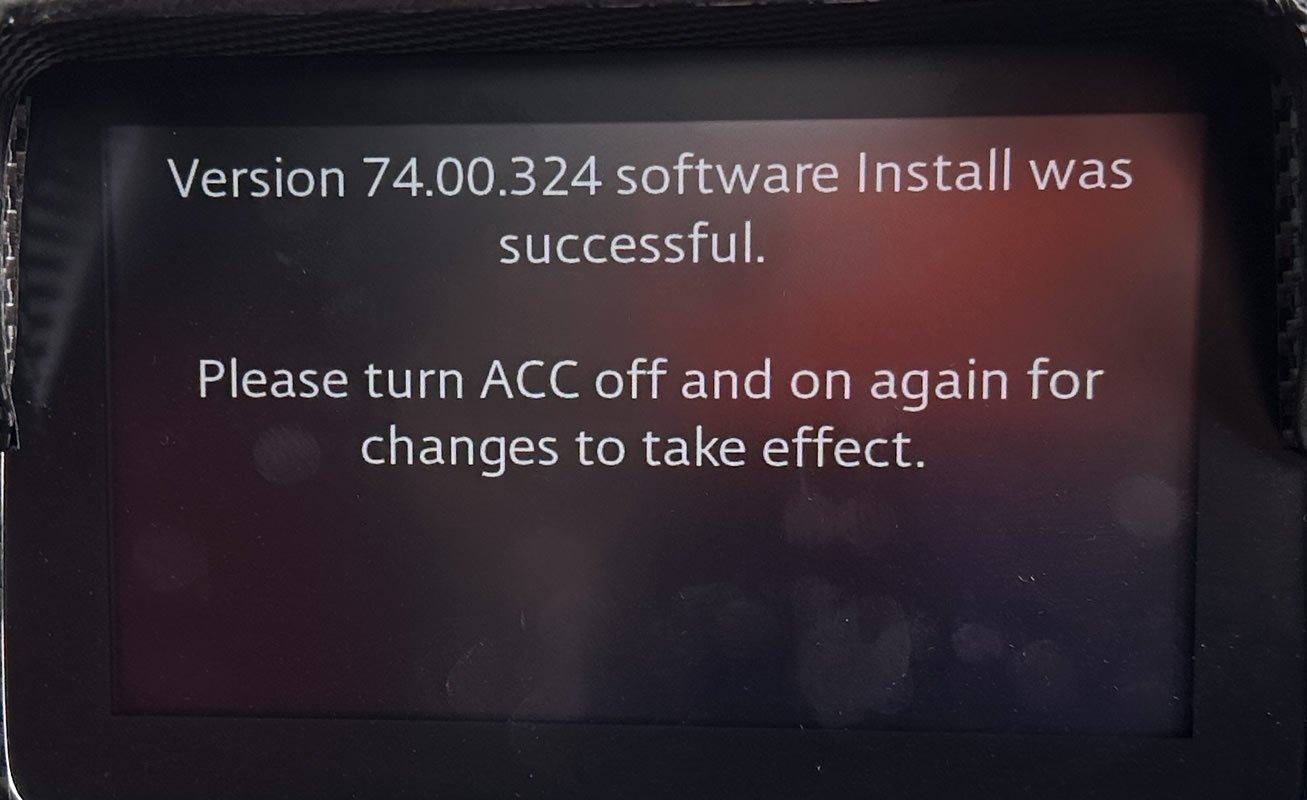

Last time I left the update to cook and popped back every 15 minutes to press the clutch pedal, this time I decided to stay in the car. After approx 45 minutes, the update was completed and the success message below was displayed. It's always great to see a confirmation like this.

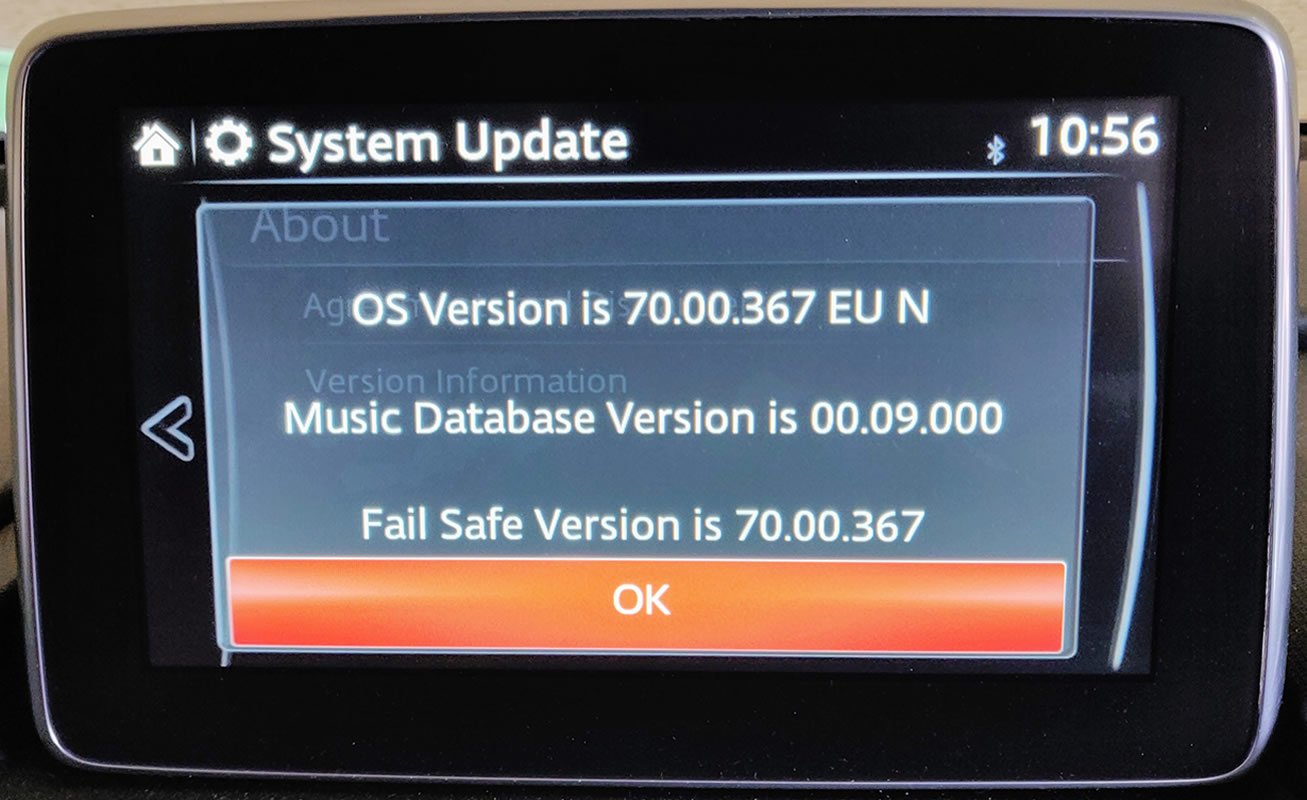

After rebooting the system - a.k.a turn off the ignition and turn it back on. I verified the new version was showing as expected.

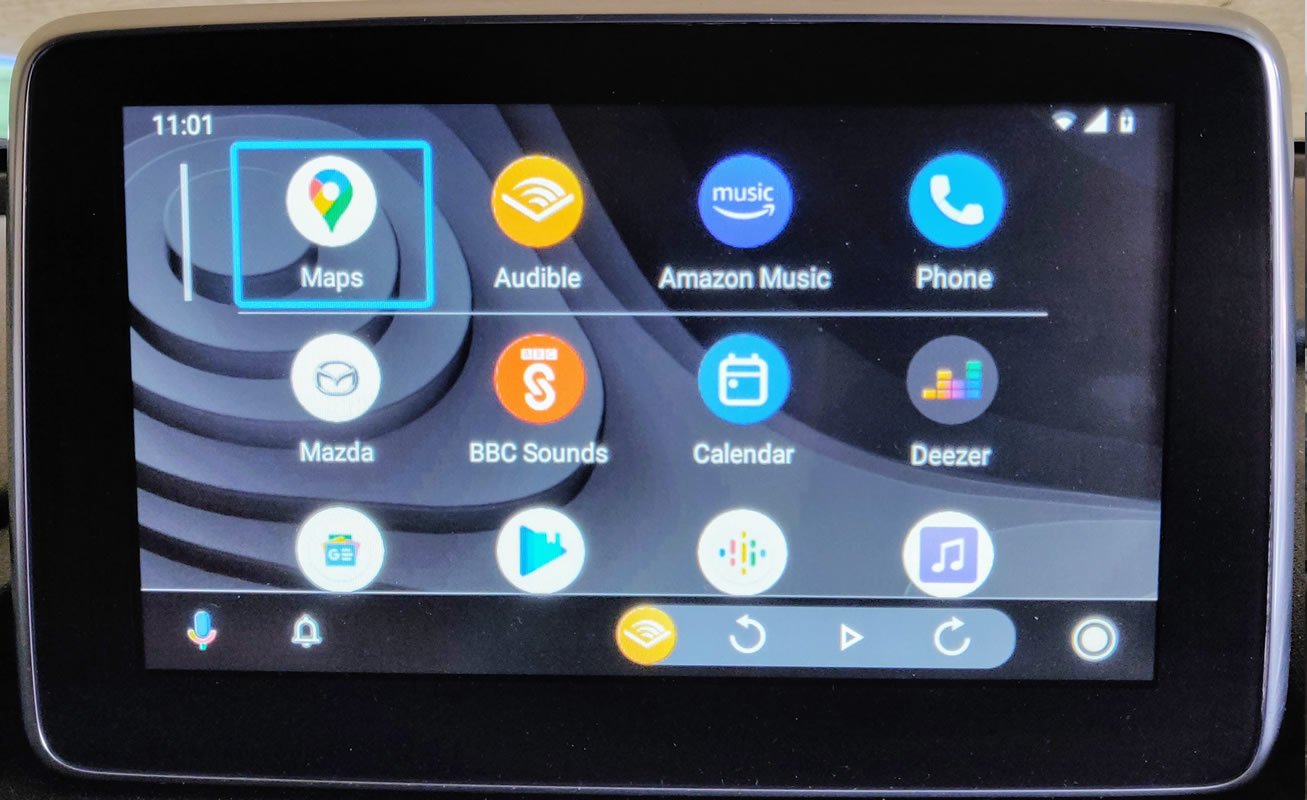

I don't have a list of things that will be new and improved. I wish I did, but the update file didn't come with a changelog. So far I've noticed the boot screen has a different loading image, but Apple CarPlay doesn't look majorly different, which isn't surprising. I guess I'll spot more differences while I'm out on the road, queuing at one of the never-ending sets of roadworks we have in our part of the UK.